Tensor Maxtensor MX2

The MAXTENSOR® MX2 tensioner and connector is specially designed to connect and tension wire in vineyard trellis installations, wire mesh weaving in agricultural and livestock fences. It also allows the repair of damaged sections of wire in trellises, fences and fences among others. It has a small separation between cables that facilitates their conduction and tensioning, allowing the tool to be placed comfortably, as well as protecting the wires against points of accelerated corrosion.

The internal mechanism of the MAXTENSOR® MX2 connector tensioner allows the wire to progress freely in the direction of the arrow and locks immediately when pulled in the opposite direction. It is designed to facilitate wire entry.

All MAXTENSOR® products are designed and manufactured in Spain using high quality materials that provide a long life under rigorous working conditions.

Thanks to their patented design, they are up to 70% faster than traditional tensioning systems on the market.

All the components used in its manufacture are metallic. This feature makes them reliable, robust and durable with high resistance to mechanical wear and environmental corrosion.

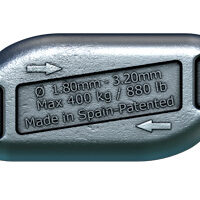

Wire diameter range Tensor Maxtensor MX2

The range of wire diameters supported by the Maxtensor MX2 tensioner is 1.8 – 3.2 mm.

The limit load supported is 400 Kg.

Tips for using the MX2 tensioner

When planning the installation with Maxtensor® terminals and tensioners, you should consider the following tips for use.

The range of connectors and wire tensioners are useful with most wires for agricultural use in trellises, fences, or support wires. Given the diversity of wire types on the market, it is recommended to consult the technical department of Juma Metal, S.L. on which would be the ideal product depending on the application and the type of wire used.

Do not exceed the load limit of the product.

The indicated load limit is a static load value, and is calculated based on the type of wire and diameter used. If you believe that the product will be subjected to high workloads, use wire diameters close to the maximum value of the range indicated on the product. In case of doubt, it is recommended to consult the technical department of Juma Metal, S.L. on what would be the recommended product depending on the application and the type of wire used.

Take into account that dynamic loads produced by the wind, impacts, vibrations that could considerably increase the service loads on the wire affecting the operation of the device.

Keep in mind the various factors that can affect the correct operation of the product due to dirt such as chemicals and insects among others.

Do not use the product outside the diameter range recommended by the manufacturer.

Leave a minimum safety length of 10 cm from the free end of the wire to the exit hole of the product.

Regularly check the status of the installation.

Secure the free ends of excess wire.